Clocking the Invisible: Why a Real-Time Dust Monitoring Device is Your Greatest Safety Asset

Introduction: The Cost of Waiting for Data

For decades, industrial safety relied on traditional gravimetric dust monitoring—a process that involves collecting dust samples on a filter over 8 or 24 hours, and then waiting days for lab results. In a modern industrial environment, waiting days for data that concerns worker health and regulatory compliance is an unacceptable risk.

The solution is the adoption of real-time air quality technology. A professional Real Time Dust Monitor provides instantaneous, continuous feedback on airborne particulate levels, allowing safety managers to move from reactive risk management to proactive control. This blog explores how a Real-Time Dust Monitoring Device can revolutionize your safety protocols, drive compliance, and boost operational efficiency.

1. The Critical Advantage of Real-Time Monitoring

The core benefit of a Real Time Dust Monitor is the immediacy of its data. This speed is crucial for several critical functions:

-

Instant Intervention: If a process change (like starting a grinder or a vehicle movement) causes an unexpected dust spike, the real-time monitor alerts personnel immediately. This allows for rapid adjustments to dust suppression systems, ventilation, or work practices, preventing prolonged worker exposure and boundary breaches.

-

Compliance Certainty: Regulatory bodies often set Time-Weighted Average (TWA) exposure limits. Continuous monitoring provides the granularity needed to prove that, despite short spikes, the overall TWA remained within permissible limits, safeguarding the company against potential fines.

-

Active Control Verification: Managers can test the effectiveness of new safety controls (e.g., a new water misting system or ventilation shroud) and see the data reflected instantly. This cuts down on the trial-and-error cycle inherent in traditional testing.

-

Identifying Specific Hazards: By linking real-time data to a worker’s activity log or time-stamped video footage (as seen in personal monitoring systems), you can identify which specific tasks are causing the highest exposure—a crucial step in preventing serious occupational diseases like silicosis.

2. Technology Behind the Speed: The Real-Time Dust Monitoring Device

The technology that powers this instant feedback is typically an Optical Particle Counter (OPC) using the principle of laser scattering.

-

Air Intake: A constant flow pump draws a precisely measured volume of air into the device.

-

Laser Interaction: The airborne particles pass through a focused laser beam inside a sensor chamber.

-

Light Scattering: When a particle crosses the beam, it scatters the light. A detector measures the intensity and angle of this scattered light.

-

Mass Concentration: The device’s algorithm translates the scattered light signature into a mass concentration for specific particle sizes (PM10, PM2.5, etc.), providing a reading instantly.

This process allows the Real-Time Dust Monitoring Device to provide continuous updates, eliminating the multi-day wait associated with off-site lab analysis. Furthermore, advanced units often integrate temperature and humidity sensors, providing critical context to the air quality data.

3. Key Applications Where Real-Time Data is Critical

The versatility of a Real Time Dust Monitor allows it to be deployed across a wide range of high-risk scenarios:

-

Personal Exposure Monitoring: Workers wear compact real-time monitors in their breathing zone. If the exposure limit is breached, they receive an immediate alert, allowing them to adjust their task or don appropriate PPE, significantly reducing the risk of illness.

-

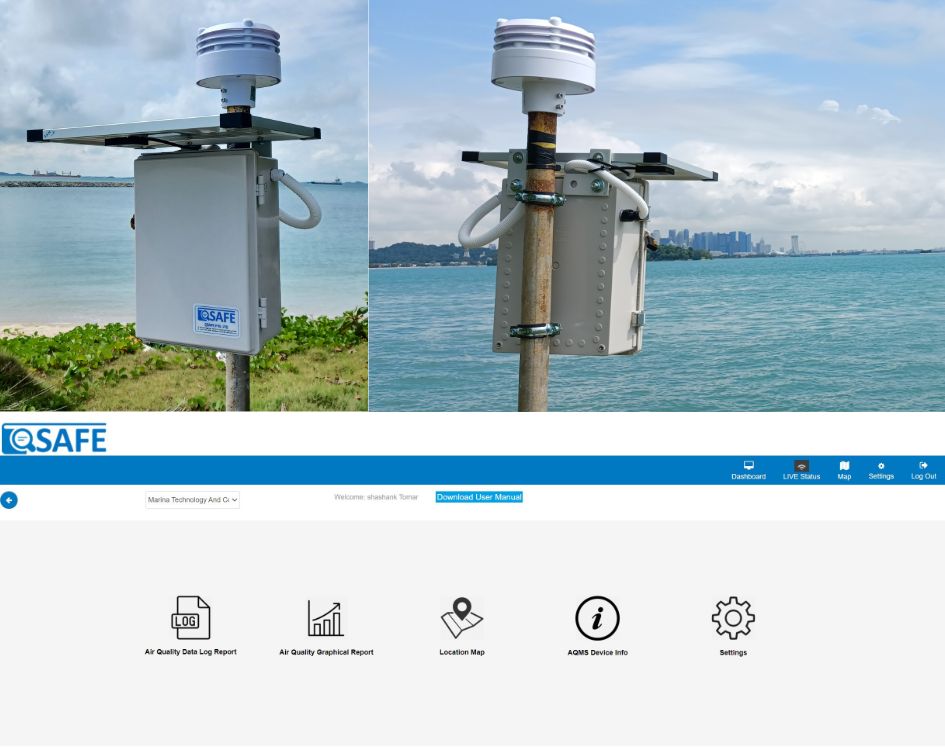

Construction Site Boundary Monitoring: Fixed Real Time Dust Monitor stations are placed on site perimeters to track emissions impacting surrounding communities. The system automatically triggers alerts if dust plumes drift off-site, allowing the operator to stop work or activate suppression immediately.

-

Process Optimization: In manufacturing, real-time data is used to optimize dust control systems (like dust collectors). By monitoring the PM level at the collector’s outlet, companies can ensure filters are performing efficiently and plan maintenance proactively, saving energy and avoiding costly shutdowns.

-

Emergency Response: In cases of equipment failure (e.g., a ruptured exhaust pipe or ventilation collapse), the immediate spike detected by the Real-Time Dust Monitoring Device triggers a site-wide alarm faster than any visual inspection, protecting all personnel instantly.

Conclusion: Making Informed Decisions Instantly

The era of delayed dust monitoring is over. With hazardous dust exposure under increasing regulatory scrutiny worldwide, the ability to instantly capture, analyze, and act on data is the new standard.

Investing in a professional Real Time Dust Monitor is about more than just compliance; it’s about creating a culture of active protection. It provides you with the visibility to identify a problem the moment it begins and the intelligence to implement the most effective, cost-efficient solution.

👉 Ready to move beyond slow sampling?

Upgrade your safety protocols today with a cutting-edge Real-Time Dust Monitoring Device.